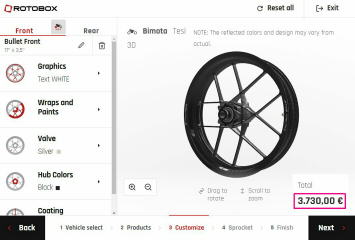

TESI 3D

TESI 3D

machined & carbon fiber No.11/29

I replaced the cam/crank angle sensor with a 40-tooth

photo-interrupter and the sync loss disappeared,

and the Speeduino started working properly,

so I've summarized my experience over the past

three years since I bought it.

July 2022

I found it on GooBike and bought it at a shop in Kawasaki, Kanagawa. It's the

11th of the 29 LEs (Limited Edition, called Concept in Japan) that were

first made. I ran out of gas on the way back from the shop😃 I got

the money from an 1198SP, a MHR Mille, and some other things I sold on

Yahoo Auctions that I didn't need.

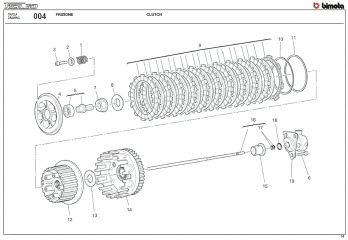

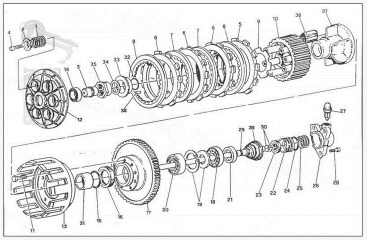

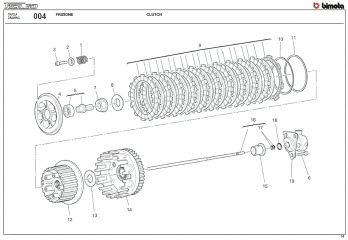

Since the LE has a wet clutch, I considered from the time of purchase whether it could be modified to a dry clutch.

August 2022

Purchased and replaced a ZARD silencer on Ebay.

I found out that the tank cap was

compatible with the Aprilia RS250, so I immediately purchased one on

Amazon and replaced it with the logo sandblasted on.

September 2022

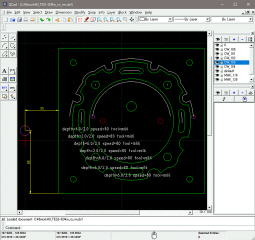

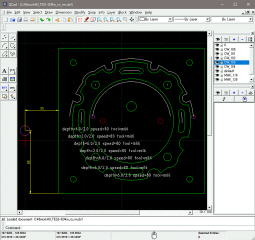

The heel guard was measured, a blueprint was made, and it was cut out of carbon plate using a CNC milling machine.

October 2022

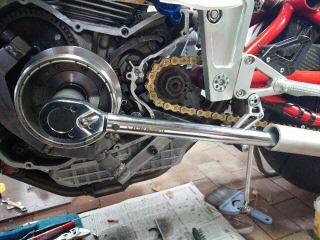

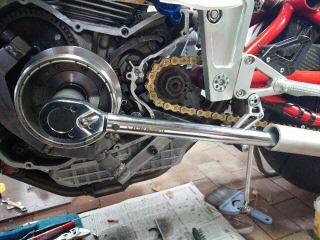

I had the drive chain replaced at my favorite shop in Mitaka, Tokyo.

November 2022

I went on a tour to Mount Akagi in Gunma Prefecture with my high school friend Y (CB400).

January 2023

Ordered a slipper clutch for dry clutch conversion on Ebay.

February 2023

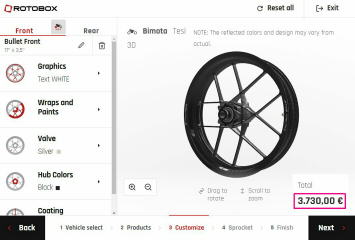

I ordered Rotobox carbon wheels from the shop in Kawasaki, Kanagawa Prefecture where I purchased my TESI.

March 2023

The belt cover has been made clear to improve maintainability.

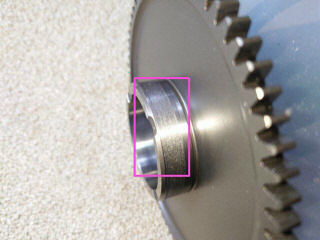

I made a special nut and completed the conversion to a dry clutch. It wasn't as easy as I thought it would be.

Using Sunstar's Monkey 125 brake

rotor, I made the rear brake rotor floating. Since the size of the

inner rotor is larger than the travel distance of the milling machine,

it was cut in two steps. The inner rotor was surface treated with red

hard anodizing. The cost of hard anodizing was 19,000 yen, which is

quite expensive.

I replaced the master cylinder with a Brembo one and competed on Yahoo Auctions, but the price went up quite a bit😃

April 2023

On the way to the emission inspection shop, TESI was towed away due

to an oil leak 😃 The cause was a loose oil seal on the clutch rod.

The exhaust gas had a high concentration of CO and HC, so we gave up on the user inspection and went for a private inspection.

May 2023

I took it to the shop in Kawasaki, Kanagawa where I bought the TESI to have the wheels replaced.

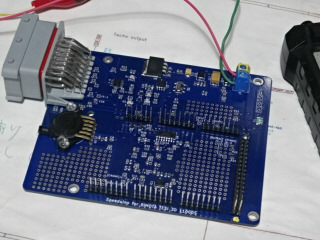

Started researching and making Speeduino. I already had the CPU boards for the Arduino MEGA and UNO shown below.

June 2023

Wheel replacement completed, I took the train to the shop in Kawasaki to pick it up.

The oil cooler bracket was remade from carbon fiber based on the original.

July 2023

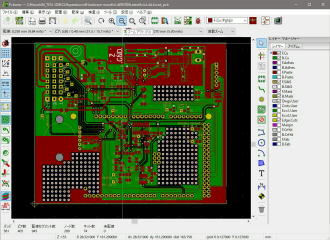

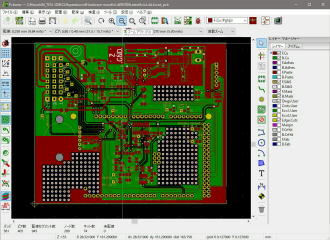

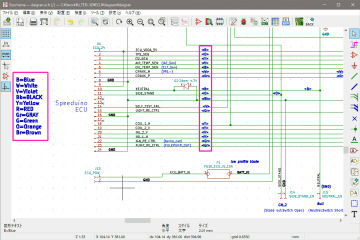

The artwork on the

Speeduino baseboard has been changed to suit a two-cylinder engine.A

universal part has been added to the empty space.

August 2023

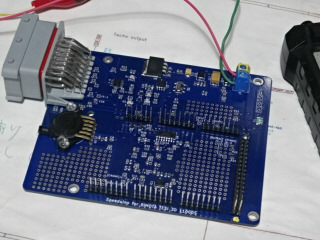

Component installation on the speeduino base board completed.

November 2023

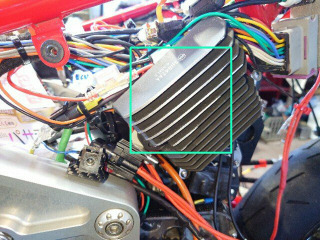

The Speeduino ECU is completed after being placed in the case.

February 2024

Purchased a KOSO RX-4 meter unit from a Japanese distributor to coincide with the Speeduino.

The front fender bracket was remade from carbon fiber based on the original.

April 2024

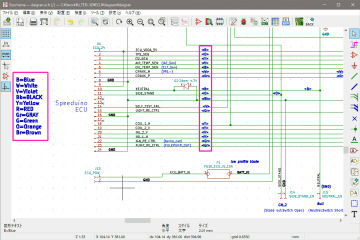

Confirmed that the engine can be started with Speeduino (Arduino MEGA

CPU) by reconnecting the TPS, cam angle, ignition, and injection

signals.

Created a wiring diagram for the Speeduino and started making the harness.

The Speedino's cam angle pulse has been changed from the original 48-2 missing tooth to a 36 tooth dual wheel with hall sensor.

May 2024

The engine started with a 36-tooth dual wheel Speeduino (Arduino MEGA

CPU) after changing only the TPS, cam angle, ignition, and injection

connections.

July 2024

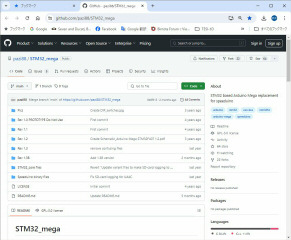

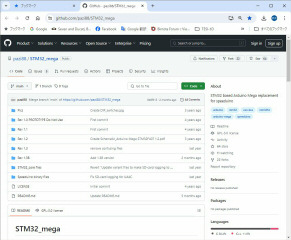

Started investigating the STM32 version of Speeduino. On the right is

Pazi88's YouTube video. On the left is the hardware GitHub.

STM32 version CPU board implementation completed.

October 2024

Engine start confirmed using the new harness and Speeduino (Arduino MEGA CPU).

First test run with the STM32 version of Speeduino. I found that it ran surprisingly well.

December 2024

Purchased a non-slip clutch to prevent judder on Ebay.

The basket and clutch plate were replaced, leaving the slipper mechanism intact. Judder was eliminated.

January 2025

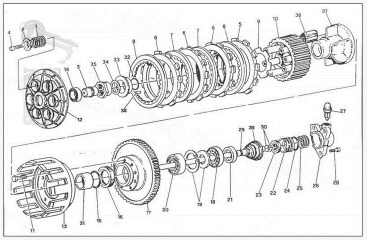

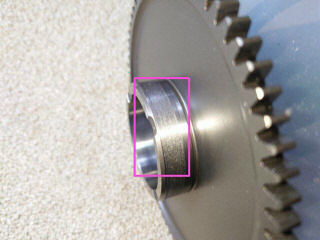

Due to the heavy use of the one-way clutch to check for overlapping

pulses during cranking in the winter, the one-way clutch slipped and

the engine could not be started. Upon disassembly, it was found that

not only the one-way clutch but also the starter driven gear and flange

were worn out.

I purchased a complete used one-way clutch for a Multistrada 1100 on Ebay.

February 2025

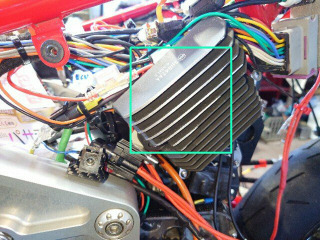

Replaced with an open type regulator. I shaved off a little of the heat sink fins and it just barely fit.

Used Multistrada 1100 starter driven gear, replaced with a new one-way clutch and flange from AliExpress.

March 2025

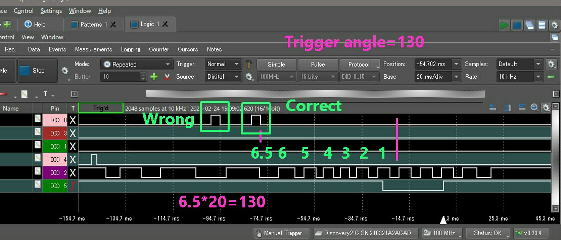

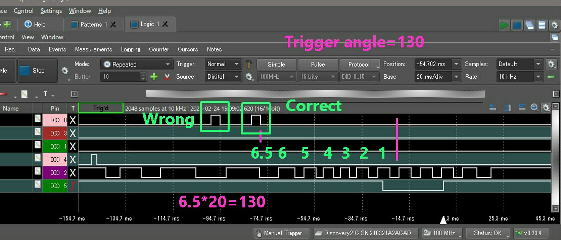

It was discovered that overlapping ignition pulses during cranking were caused by rotational fluctuations.

Passed user vehicle inspection with Speeduino (STM32 CPU).

May 2025

Switched to direct ignition to prevent occasional sync loss.

Afterwards, it was discovered that the cause of the sync loss was not

external noise.

June 2025

To prevent sink loss, the cam/crank angle pulse has been changed from a hall sensor to a 40-tooth photo-interrupter.

I bought a spare engine for a Multistrada 1100 on Yahoo Auctions. There was a lot of competition and it was quite expensive.

<Speeduino problems and solutions>

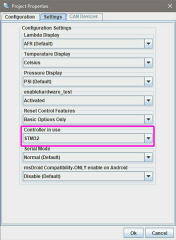

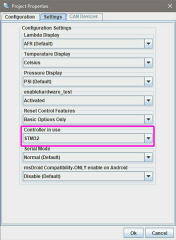

-SD card not recognized

I set the board layout of TunerStudio to BWMPnP only, and forgot to set

the controller settings below to STM32. It was just a setting mistake.

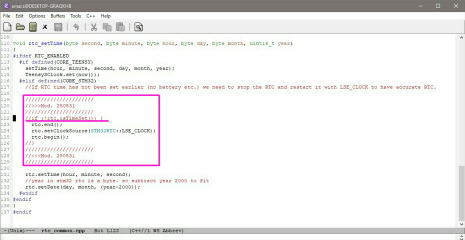

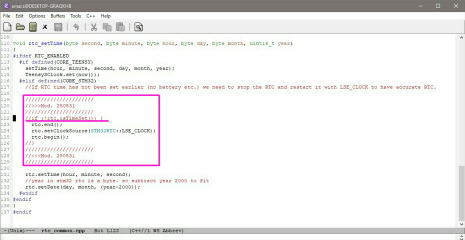

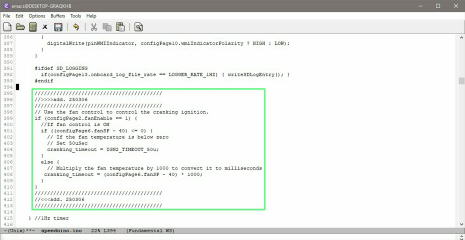

-RTC misalignment of STM32

This is not a fundamental solution, but by removing the underlined

conditions and modifying the code so that the code in the red box

always runs, the problem is greatly improved and practically solved.

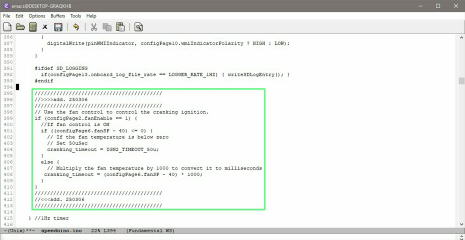

-Overlapping ignition pulses during cranking Initially

At first, starter motor noise was suspected, but it turned out to be due

to rotation fluctuations during cranking. I modified the source code

so that it ignites only once at the specified primary pulse position.

I also modified it so that the primary pulse position and timeout can

be specified using TunerStudio's FAN control.

・Speeduino sync loss

At

first, ignition noise was suspected, but it was later determined that

the cam/crank angle pulse hall sensor was installed too close, causing

interference. The sensor was changed to a 40-tooth dual wheel photo

interrupter. After that, five test runs were conducted and it was

confirmed that there was no sink loss.